wire edm machine working principle

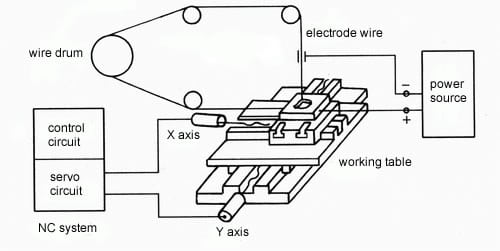

CNC wire cut EDM machine puts impulse voltage between electrode wire and workpiece through impulse source controlled by servo. Wire EDM which came into commercial use.

Pdf Review Of Wire Cut Edm Process On Titanium Alloy Semantic Scholar

Working of Electrical Discharge Machining EDM In EDM first the tool and wp is clamped to the machine.

. For quality parts delivered on time choose Xometry cnc machining services. Makino EDMs have a streamlined and efficient interface that helps work get done faster. Electrical discharge machining EDM is a new technology that uses electric energy and heat energy to process.

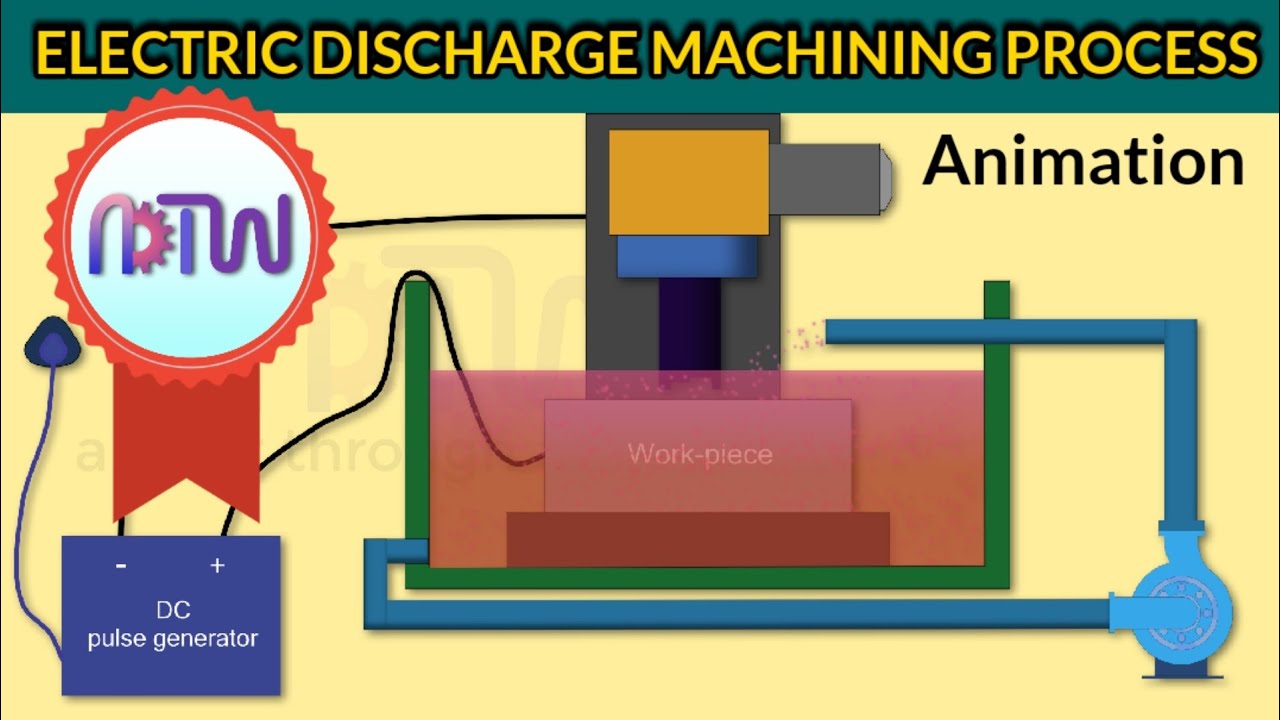

Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges. Principle of wire cut EDM. The basic principle behind this process is the erosion of the material with a controlled electric spark.

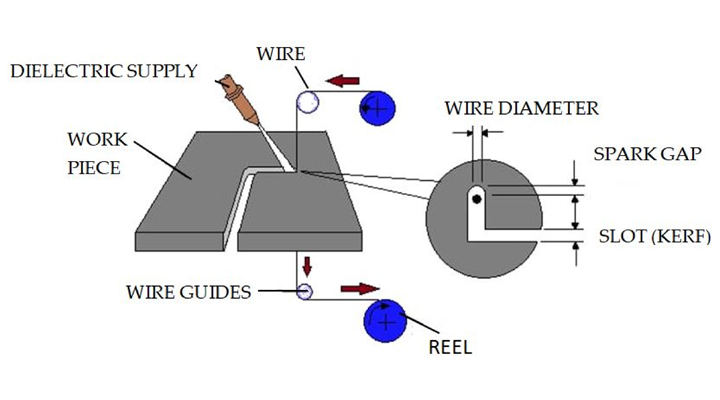

Wire EDM creates a spark in deionised water in which conductivity is highly controlled. Ad Faster processing times superior surface finishes for the most complex part geometries. A wire cutter also.

The Spark Theory on a wire EDM is basically the same as that of the vertical EDM process. The supply of dielectri. No actual contact is made between the wire and.

For this to occur the two electrodes must not come in contact. The difference between electrical discharge machining and. The wire is monitored precisely by a computer-numerically controlled CNC system.

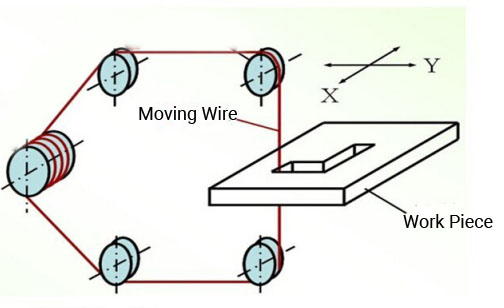

Wire EDM creates a spark in deionised water in which conductivity is highly controlled. How Wire EDM Works Wire EDM uses a traveling wire electrode that passes through the work piece. The deionised water cools the material and washes away the removed particles.

Wire edm machine working principle. Once the desired dimensions are achieved the wire EDM machine. Ad Full suite of CNC machining services including the latest in wire EDM machining.

Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece. Working Principle of Electrical Discharge Machining Process. The use of precisely focused electrical discharges makes it possible to make complex or intricate shapes and patterns.

Wire EDM also known as Wire-Cut EDM works in a very similar way using a rapidly charged conductive metal wire to melt the material. Your Wire EDM machine uses a thin electrically conductive wire generally brass as an electrode to cut the workpiece to create the desired profile or shape. Wire cut EDM equipment is run by computer numerically controlled CNC instruments which can control the wire on a three-dimensional axis to provide greater.

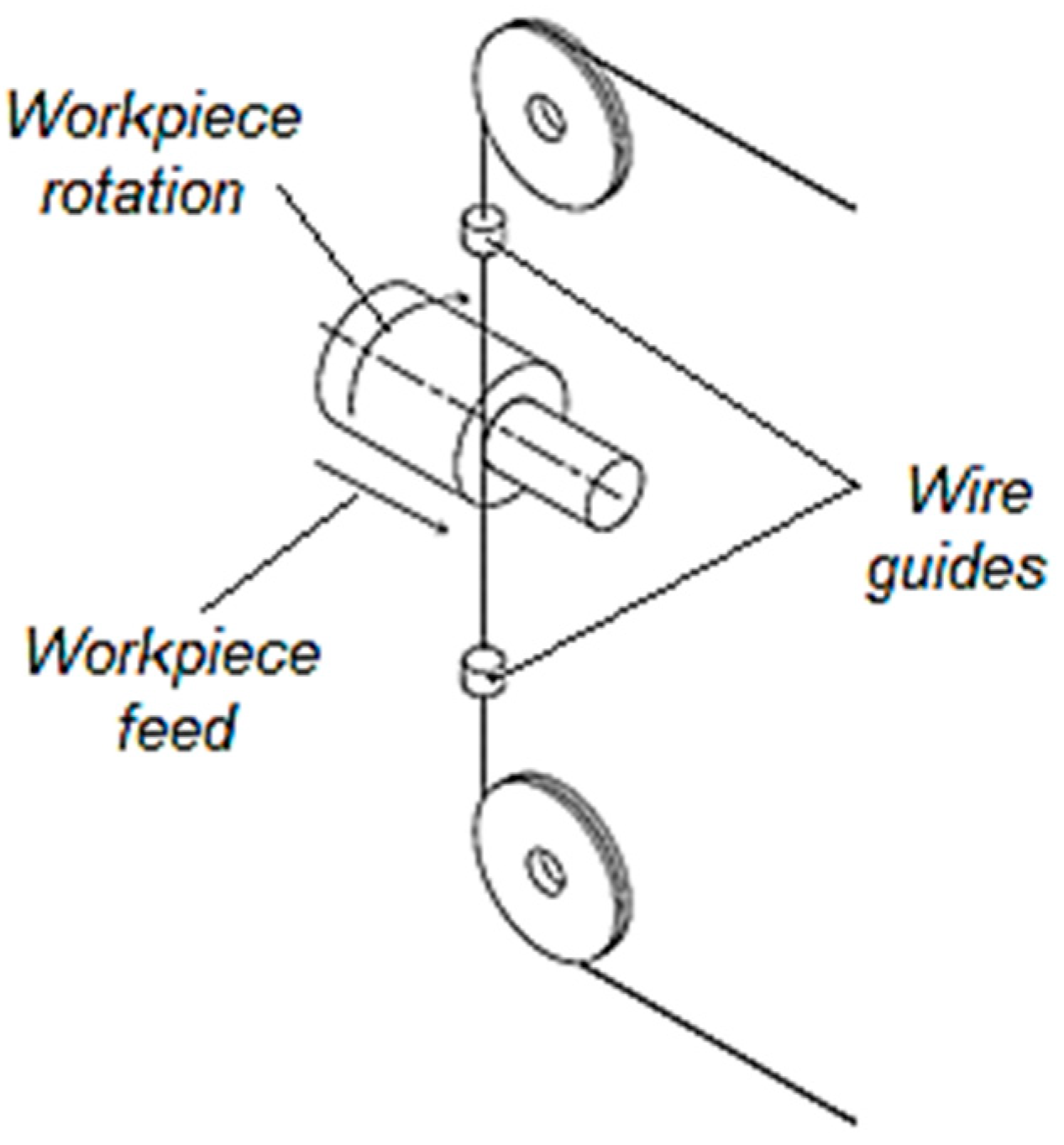

The working principle of wire EDM is same as that of conventional EDM except that it uses a small diameter wire about 002 03 mm as electrode and deionized water as. Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece. The EDM machine controls the movement of the electrode and a dielectric fluid to cool the workpiece and electrode.

As the spark jumps across the gap material is then removed from the work. The Five Benefits of Using a Wire EDM. The deionised water cools the material and washes away the removed particles.

A metallic wire usually brass or copper. This kind machines working principle is to use the continuously moving. The deionised water cools the material and washes away.

Ad Faster processing times superior surface finishes for the most complex part geometries. Electrical Discharge Machining EDM is a non traditional machining and electro thermal process in which material from the workpiece is removed by using electrical. It is suitable for thermoelectric.

After that with the help of a servo mechanism a small gap of human hair is maintain. Makino EDMs have a streamlined and efficient interface that helps work get done faster. The basic working principle is to use a continuously moving thin metal wire called an electrode wire as an electrode to perform pulse spark discharge on the workpiece to.

A wire cutter also known as a wire EDM is based off the same principle as a traditional EDM.

Machines Free Full Text Wire Electrical Discharge Machining A Review Html

Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Electrical Discharge Machining Principle Working Equipment S Advantages And Disadvantages With Diagram Mech4study

Sinker Edm Vs Wire Cut Edm What Is The Difference Dek

Edm Machine Video Edm Molding Professional Performance

What Is Edm Machining Wire Edm 101 Sans

Wire Edm Find Suppliers Processes Material

Electrical Discharge Machining Principles And Applications Rapiddirect

Electrical Discharge Machining How Edm Machine Works

What Is Wire Edm Electrical Discharge Machining Xact

Wire Edm Find Suppliers Processes Material

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Mechanical Engineering Electrical Discharge Machining Edm Principles

Electrical Discharge Machining Principles And Applications Rapiddirect

Ultrasonic Plastic Welder For Us Plastic Welding Bonding Solutions Plastic Welding Welding Equipment Ultrasonic Welding